Experiential Learning Lab

The Experiential Learning Lab in Upson Hall is at the center of Student Project Team life . This flexible workspace includes build, meeting, and storage space expressly for the Project teams. These spaces include the GM Automotive Lab, where the Cornell Baja Racing and FSAE Racing teams work their magic, and the Composites Lab, which provides a well-equipped space for teams to work safely with a variety of materials including carbon fiber and fiberglass, metal, paint, enamel, and other chemicals.

Campus Lab Facilities

-

![Student in protective glasses works at metal equipment]()

Manufacturing and Learning Studio

The Manufacturing and Learning Studio of the Sibley School of Mechanical and Aerospace Engineering is equipped with standard milling machines, lathes, high-end CNC machines, and a host of support equipment, this machine shop is professionally staffed and provides thorough training to all who use it.

-

![Students work together around a table in the Rapid Prototyping Lab]()

Rapid Prototyping Lab

The Rapid Prototyping Lab is a state-of-the-art 3D printing lab. Operated by undergraduate engineering students, the Rapid Prototyping Lab provides a variety of 3D printers, a laser cutter, and a CNC router table.

-

![Student walking in front of Tang Hall]()

Meinig School Design Complex

The Meinig School Design Complex in Tang Hall provides state-of-the-art laboratory space for our medical device teams.

-

![Students work together to measure the performance of a pump system in the unit operations lab]()

Chemical and Biomolecular Engineering Unit Operations Laboratory

ChemE Car members develop and test the chemical designs that fuel their vehicle in the Unit Operations Lab in Olin Hall, home of the R.F. Smith School of Chemical and Biomolecular Engineering.

-

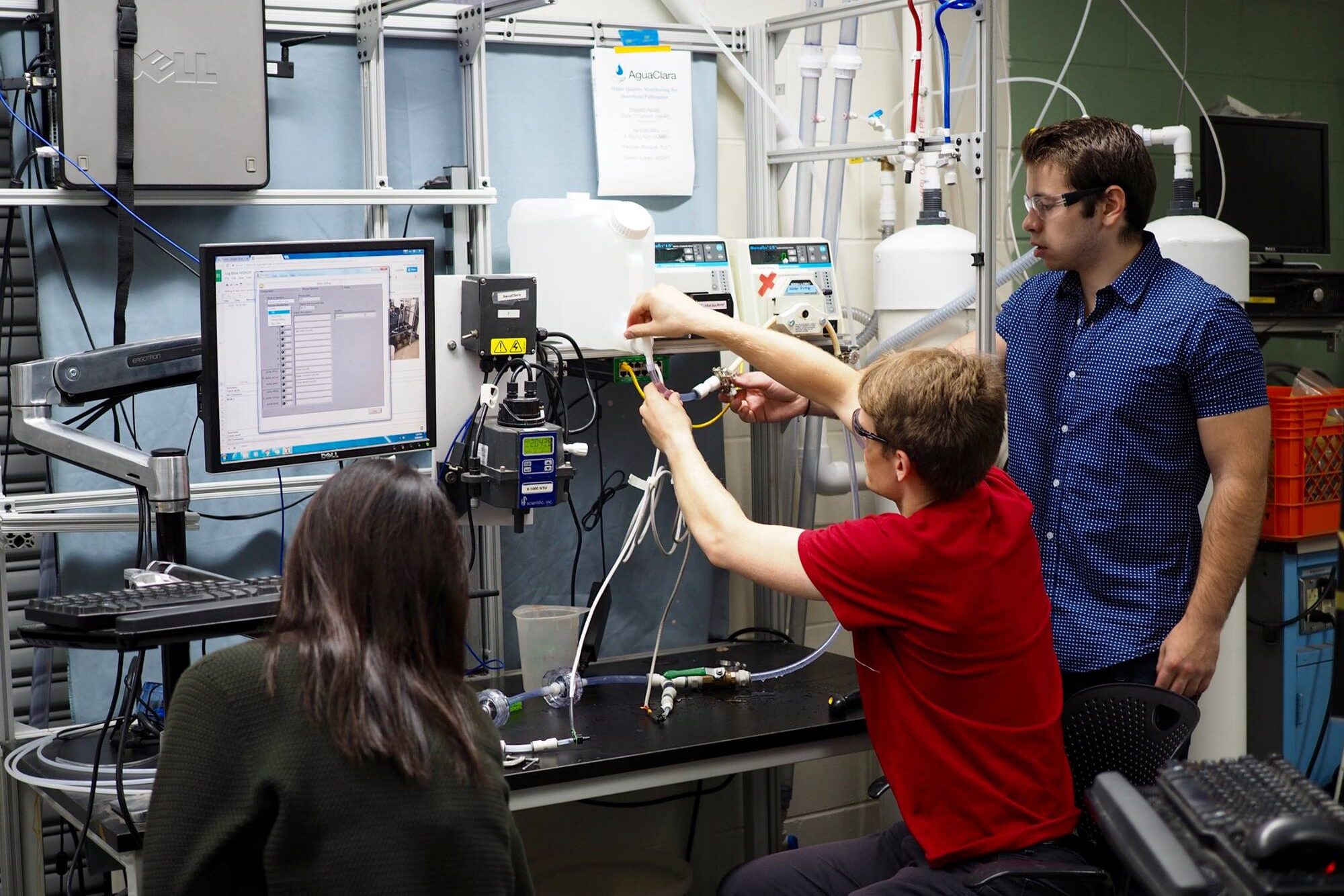

![Three students work together on a water quality monitoring system]()

Civil and Environmental Engineering Environmental Teaching Lab

Members of Agua Clara work in a dedicated portion of Civil and Environmental Engineering’s Environmental Teaching Lab in Hollister Hall.

-

![Current students in the American Society of Civil Engineers work in Cornell's High Voltage Lab on Mitchell Street to build new parts for the Flat Rock Bridge. The student chapter of the American Society of Civil Engineers (ASCE) built the Flat Rock pedestrian bridge in 1983 - now the current ASCE students are working to renovate it for the next 40 years, with the help of alumni from the class of '83, retired and current faculty from the department of civil and environmental engineering, and the local Ithaca ASCE chapter.]()

High Voltage Lab

Cornell’s High Voltage Laboratory is a repurposed facility that provides an open high-bay workspace for several teams with large-scale build projects including Concrete Canoe, CUAD, Solar Boat, and Steel Bridge.

Additional Testing Locations on Campus and Beyond

On land, underwater, and in the sky, project teams continuously test and validate their design and build work. With College and University support and dedicated community partners, students find a wide variety of safe, creative locations to drive, submerge, and fly.